Printed circuit boards or “PCBs” have various significant advantages, mainly when referring to the old ways of building electronics.

A while back, every component that had been inside an electronic device had to be connected with massive wires and placed wherever they could fit.

PCBs have an entirely different approach, and they do use large amounts of space.

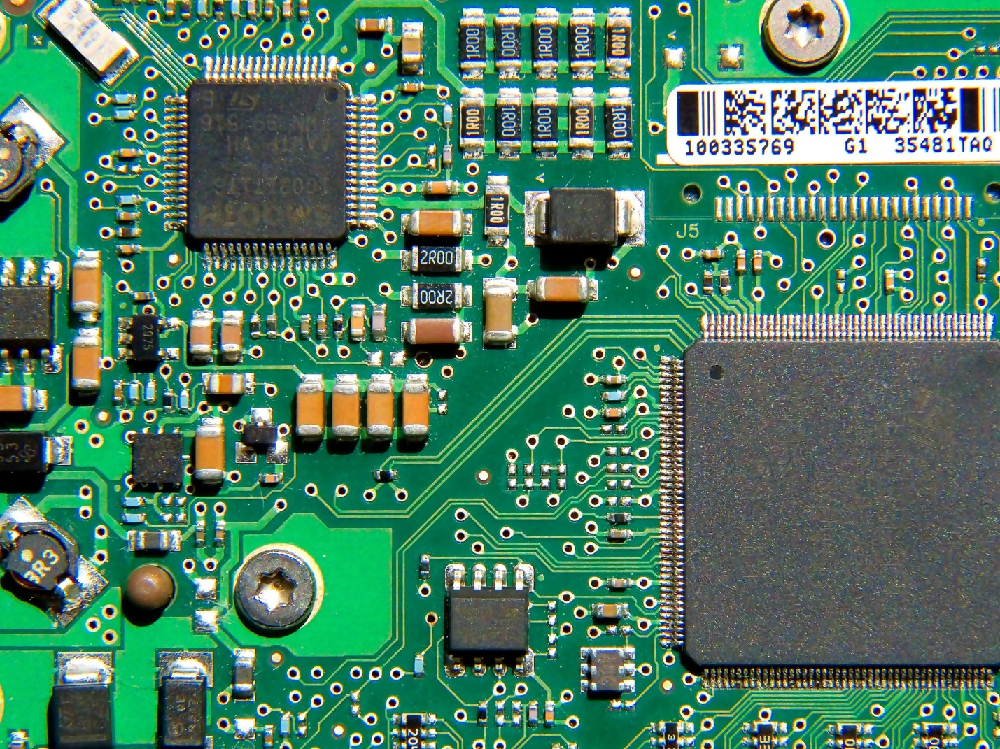

The components are mounted on something that’s called a non-conductive board, which connects with microscopic pathways, and are “traces” because they are on a PC.

Printed circuit boards accommodate and fit numerous components in a short amount of time and space.

PCBs and how they work?

Printed circuit board is a traditional name for a bare board, which you use to mount components on and layout data. A PCB is used to assist in mechanical support and to electrically connect the electronic components by using conductive pathways, tracks, or even signal traces.

A PCB is one of the most common names, although it’s also called “printed wiring boards.” PCB circuits were constructed via a laborious process from point to point wiring, which led to constant failures with wire junctions and short courses, and wire insulation began to crack, get brittle, and age.

PCBs had moved electronics from relays to vacuum tubes and integrated circuits, and then the cost of electronic components and size started to decrease. Electronics became much more prevalent in consumer merchandise.

PCBs are a variety of electrical components produced in manufacturing. And each is very important when relating to the functionality of a device and to which it belongs. In its most basic form, a PCB is a plastic board that has a covering in fibreglass. PCBs also have tiny holes drilled where the components need to be.

Suppose the circuit board is a one-sided board; in that case, it has a layer of conducting materials and copper; on the other, multiple electronic components are on the board for incorporation.

A double-sided PCB can mount conductive elements on both sides of the board instead of just one side. PCBs allow closer routing for traces as they can alternate between the bottom and the top layers. The components themselves are reasonably necessary on each type of individual board and are entirely essential to making these boards efficiently work in transmitting electricity and energy through these boards.

How does a PCB work?

When mentioning printed circuit boards, the traces are simply easy to notice. The thin lines are incredibly conductive and connect every component in the circuit.

Which also replaces the larger wires used in the past, as we did mention.

A printed circuit board is found in almost every electronic device. From mobile phones, computers, and smart-watches, it also provides basic technology for everything in the electronics category.

The functions of a Printed Circuit Board

Printed circuit boards allow electrical current to be routed between components on the board, replacing more significant devices and bulky wiring.

Basically, it depends, although a Pc Board can perform various tasks, including data transfer, communications, and computing. Besides, its most important function is providing a way to merge electronics for devices to be in a compact space.

Printed circuit boards are an ideal option that is less expensive than the other options and produced in high volumes and manufactured, and that’s how printed circuit boards work.

Are you looking to get your own PCB’s made? Take a look at this great PCB manufacturing AZ company now.